Lightweight steel construction – What is LSF and what are its advantages?

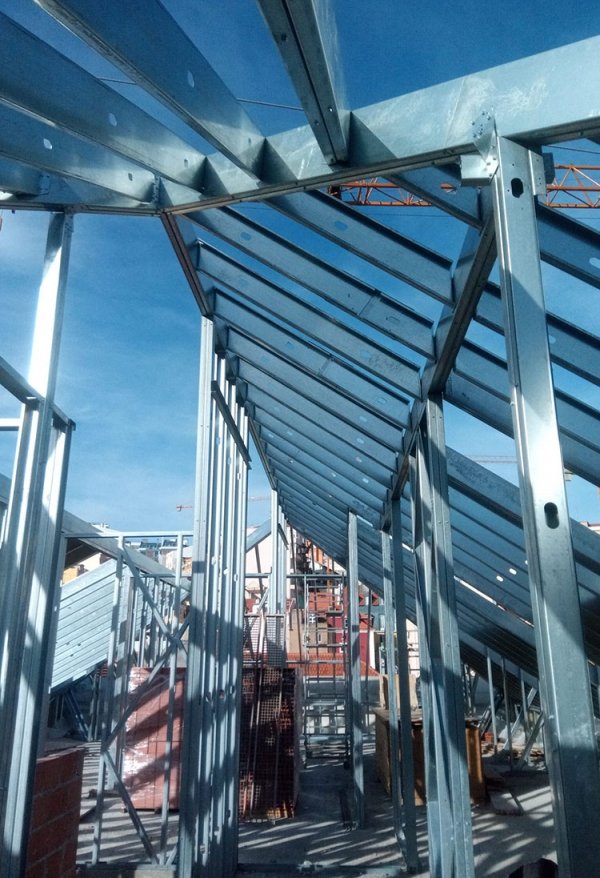

Light Steel Framing (LSF) is a construction system that uses light steel profiles as the main structural element for building construction. In this system, the structures are made of light steel profiles, typically galvanized or zinc-coated steel, designed to allow quick and efficient assembly on-site.

It is already an alternative to traditional concrete and masonry construction, offering several advantages, particularly in terms of sustainability:

Energy efficiency: LSF allows for easier incorporation of thermal insulation, reducing the energy needed for heating and cooling buildings. This leads to lower energy consumption and a reduction in greenhouse gas emissions.

Reduced material waste: LSF components are precisely manufactured off-site, minimizing construction waste. Additionally, the steel used in the system is recyclable, further lowering environmental impact.

Lower carbon emissions: The production and transportation of LSF components generate less carbon compared to conventional building materials like concrete.

Reusability and recyclability: Materials used in LSF, such as steel and insulation, can be reused or recycled at the end of a building’s life, supporting circular economy principles.

Improved indoor air quality: LSF facilitates efficient installation of ventilation systems, enhancing indoor air quality and providing a healthier environment for occupants.

Advantages of LSF over traditional construction methods include:

Faster construction: LSF uses prefabricated components that are quickly and efficiently assembled on-site, reducing overall construction time compared to traditional methods.

Lightweight: The light steel used in LSF is lighter than conventional materials, making handling, transport, and on-site assembly easier.

Architectural flexibility: LSF allows for greater design versatility, enabling open spaces, wide spans, and varied architectural forms.

Strength and durability: The steel in LSF is strong, capable of supporting significant structural loads and withstanding adverse weather, resulting in long-lasting buildings.

Reduced labor requirements: LSF requires less labor than traditional methods due to rapid assembly and the use of prefabricated components.

The adoption of LSF has grown worldwide over the past decades, with widespread use in countries such as the United States, Canada, and Australia. In Portugal, its use is relatively recent, but adoption is increasing as more industry professionals and property owners become familiar with the system’s benefits and gain experience in its application.

It is important to consider the costs of LSF construction compared to traditional methods. While the initial investment may be slightly higher due to the fabrication of light steel profiles and system assembly, the benefits often offset this cost. These include time efficiency (faster construction through quicker on-site assembly) and cost savings (reduced labor needs and less material waste) throughout the building process.

Choosing between LSF and traditional construction should consider factors such as location, project type, selected materials, available labor, durability, design flexibility, and sustainability. Each project should be evaluated individually, taking all these factors into account to determine the most suitable construction method.

Awareness of its benefits — including reduced construction waste, energy efficiency, and architectural flexibility — has contributed to the growing popularity of LSF. Will you consider using it in your next project?